Application of fiber laser cutting machine in the kitchen and bathroom industry

Published:2020-02-22 Browse:96Editor in charge:DNE Laser (Member of Bystronic)

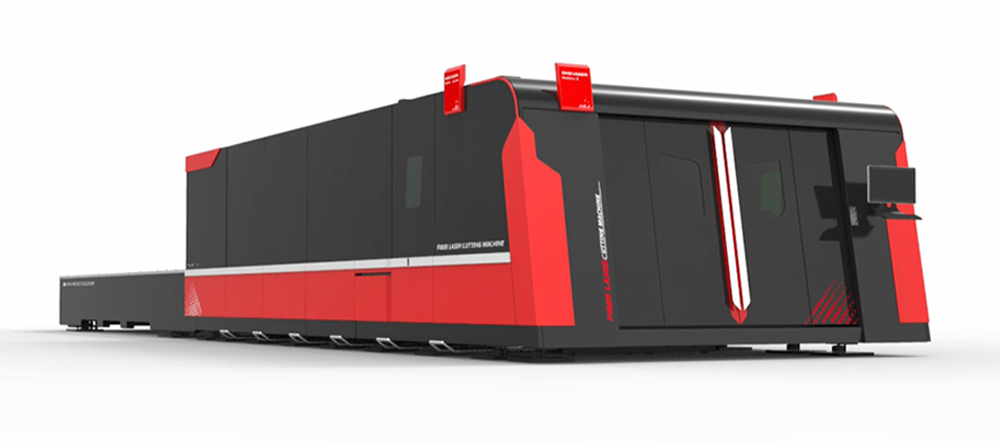

Stainless steel kitchen supplies are widely favored by the market due to their corrosion resistance, aesthetics and practicality. The traditional sheet metal processing method is cumbersome, time-consuming, and has high labor costs, which cannot meet the market demand. With the use of fiber laser cutting machines, it has brought a technological innovation to the kitchen and bathroom supplies manufacturing industry.

Cutting and shaping of stainless steel materials, pattern engraving of metal surfaces, etc., these functions can be completed by automatic programming and cutting by fiber laser cutting machine. Different from traditional processing methods, laser cutting technology has the advantages of high cutting accuracy, fast cutting speed, smooth cutting end surface, and no need for secondary processing. In addition, it should not be ignored that the laser cutting method saves a lot of costs for enterprises.

On the one hand, laser cutting does not require molds and cutters, which greatly saves the cost of mold opening. On the other hand, it is no exaggeration to say that a traditional processing plant may require 10 people and 10 days to complete the product. It takes only 1 person and 1 day by using a laser cutting machine. In the era of personalization, laser cutting technology also satisfactorily meets the customization needs of the kitchen and bathroom supplies market. Shorter production cycle, no need to make molds, reducing the time cost of mold opening, no burrs on the processed surface, no need for secondary processing, and mass production can be quickly achieved after proofing without problems.

In terms of the most mainstream sheet metal materials 304 and 306 stainless steel materials in kitchen and bathroom materials, they are widely used in products such as cooker hood panels and burner panels. The thickness is generally thin, in the range of 0.7-2mm. This kind of stainless steel sheet material is suitable for cutting with lower power fiber laser cutting machine. For thicker materials such as pool panels and other products, fiber laser cutting machines with a power of 2000W or above can be used for processing.

Bystronic (Shenzhen) Laser Technology Co., Ltd.

Bystronic (Shenzhen) Laser Technology Co., Ltd.